The Ultimate Guide to Extending Lifespan: Undercarriage Parts Upkeep Made Easy

The Ultimate Guide to Extending Lifespan: Undercarriage Parts Upkeep Made Easy

Blog Article

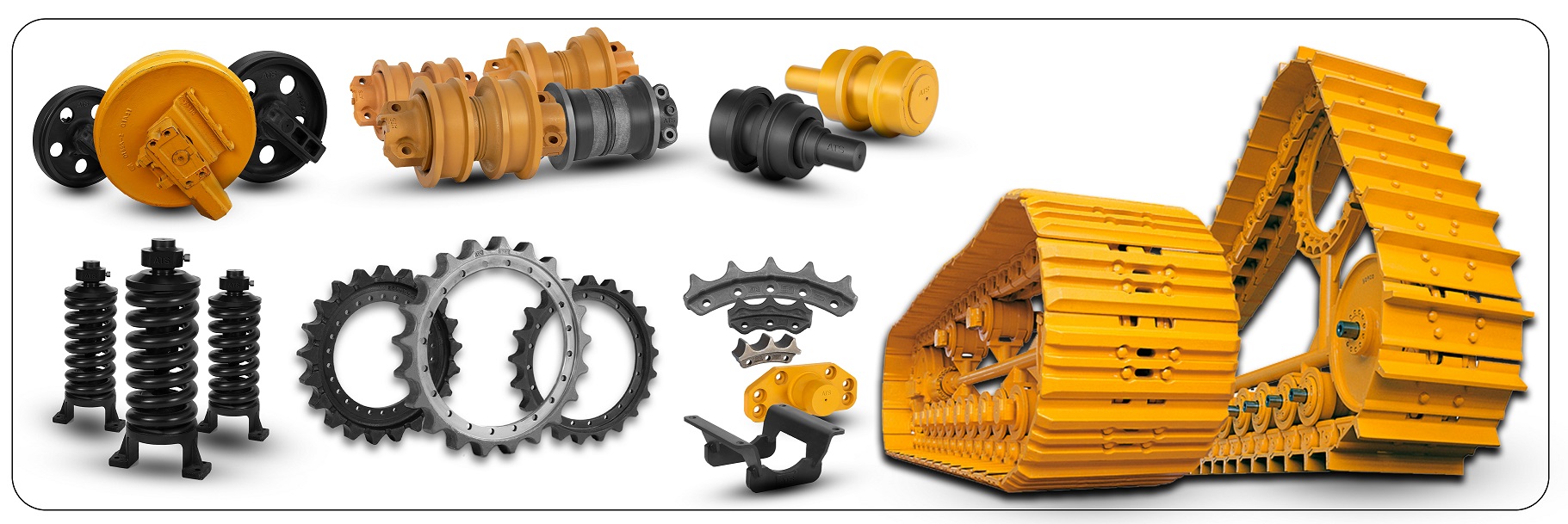

Discover Undercarriage Parts for Heavy Machinery

Comprehending the ins and outs of undercarriage components is vital for the ideal efficiency and long life of hefty equipment. From track footwear to idlers, rollers, and gears, each part plays a critical function in the capability of the tools. Exploring the specifics of these parts reveals a world of accuracy engineering and longevity that maintains hefty equipment operating at its top. Keep tuned as we discover the relevance of undercarriage parts and explore the upkeep practices that can enhance the performance of these important parts.

Relevance of Undercarriage Parts

The undercarriage components of hefty machinery play an important function in ensuring the general efficiency and longevity of the equipment. These elements, consisting of tracks, rollers, gears, chains, and idlers, create the structure upon which the device runs. A well-kept undercarriage not only supplies security and support to the hefty machinery however likewise contributes significantly to its functional efficiency and productivity.

One of the key benefits of purchasing top notch undercarriage components is the reduction of downtime and upkeep costs. By using long lasting elements that can withstand the roughness of heavy-duty applications, operators can lessen the requirement for regular repair work and replacements, therefore making best use of the machine's uptime and total lifespan.

In addition, effectively working undercarriage parts make certain optimal weight traction, distribution, and ability to move, permitting the heavy machinery to run efficiently even in difficult terrains. This reliability is crucial for markets such as mining, building and construction, and agriculture, where tools performance directly impacts project timelines and success. Finally, the importance of undercarriage components can not be overstated in preserving the performance and long life of heavy machinery.

Kinds Of Track Shoes

When taking into consideration the different sorts of track footwear for heavy equipment, it is necessary to review their design and capability in relationship to certain operational demands. Track footwear are essential elements of the undercarriage system, supplying stability, weight, and traction distribution for hefty machinery such as excavators, bulldozers, and crawler cranes.

One of the most usual sorts of track footwear consist of:

** Grouser Shoes **: Including raised metal bars (grousers) along the footwear's surface, these track shoes give boosted grip in difficult terrains like mud, snow, and loose gravel. undercarriage parts.

** Dual Grouser Shoes **: Comparable to grouser shoes but with an added set of grousers, these track shoes supply even higher traction and stability, making them suitable for exceptionally rough terrains.

** Three-way Grouser Shoes **: With three sets of grousers, these track shoes offer maximum traction and stability, making them ideal for the most demanding problems.

Picking the ideal type of track footwear is vital for enhancing the efficiency and long life of hefty equipment while making certain safety and effectiveness during operations.

Function of Rollers and Idlers

Rollers and idlers play essential functions in sustaining and directing the track shoes of heavy equipment during procedure. Rollers are round components that sustain the weight of the equipment and make sure smooth movement along the terrain. They assist disperse the device's weight equally, lowering endure the track shoes and minimizing resonances. Idlers, on the other hand, overview the track chain and aid maintain proper stress. By avoiding extreme slack or tightness in the tracks, idlers add to the general security and efficiency of the equipment (undercarriage parts).

In addition, rollers and idlers interact to keep the track footwear abreast, stopping them from sliding or hindering off throughout procedure. Effectively operating idlers and rollers are important for guaranteeing the long life of the undercarriage system and maximizing the machine's performance. Routine upkeep and assessment of these components are my link important to recognize any type of indicators of wear or damages beforehand, protecting against expensive repair services and downtime over time.

Role of Gears in Equipment

Upkeep Tips for Undercarriage Parts

Effective maintenance of undercarriage parts is vital for making certain the long life and optimal efficiency of heavy machinery. Normal evaluation of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is vital to prevent unforeseen breakdowns and pricey fixings. It is likewise important to make sure correct track stress to stop premature wear on parts.

Verdict

To conclude, the undercarriage parts of hefty machinery play a vital role in making sure the smooth performance and long life of the devices. Understanding the relevance of track shoes, gears, rollers, and idlers, along with carrying out appropriate maintenance practices, can considerably impact the try this total efficiency and performance of the machinery (undercarriage parts). Normal evaluation and timely substitute of worn-out components are vital in making the most of the life-span and performance of hefty equipment

Rollers and idlers play essential duties in supporting and guiding the track footwear of hefty machinery during procedure.In hefty equipment, gears serve an important function in transferring power from the engine to the tracks, enabling the equipment to relocate efficiently and effectively. These components are connected to the axles or final drives of the machinery and work in combination with the tracks to thrust the equipment forward or backward. Regular inspection of undercarriage Check This Out parts such as track chains, rollers, idlers, gears, and track footwear is essential to prevent expensive repair work and unforeseen breakdowns. Comprehending the relevance of track footwear, rollers, idlers, and sprockets, as well as executing appropriate upkeep techniques, can substantially influence the general performance and efficiency of the equipment.

Report this page